OK, so finally I got my hands on a Guzzi!, and it`s about time – have been wanting one for years but could not find one I really liked, the design belongs to the 1980 for sure.. But keeping stuff original have never been my stongsuit.

The worst part is that I cant even make up my mind what kind of grene i want it to sort under.. Cafè Racer.. Brat.. Tracker.. The bike has been in my workshop since the beginning of the month of May and i have ridden it a total length of 2000 Meters!

EVERYTHING has been done!

- Ebay

- 100+ Blogg`s

I have just about been “Everywhere” just to discover that my ideas has already been built by someone else.. that got that idea.. first.. hmmm, so what do I have to do to make mine stand out from the crowd, whats going to make my build so damn special that someone is going to take a closer look at it… It`s mid July.. i`m still thinking and havent left the concept phase yet.

But how do you stand out from the crowd? I thing I have narrowed it down to about 3 possible ways

- Throw money att it! Cant go wrong – right ! But tends to end up like abstract art, really dramatic, but gets old real fast, sad but true – Gold coated Lambos are cool , but for about 5 seconds…

- Everything has a history, these are the kind of bikes the owners have spent 25 years building, one bit at the time – most of them with a history attached that could fill a book.. love those builds ” Got this saddle made by locals in a village in Mongolia crossing the continent on my way to China” – But I don`t have the time…

- Nobody has what`s been made by your own hands… Some parts are easier to buy finished than to home make.. so we still need that bit in the equation – and to approach people who have unique skills that could give your build the edge it needs…

hmmmmmm….

Option nr #3…. that’s it!

Cafè Racer

Fully digital electrical system (Motogadget)

That is what I know right now.. the rest of the choices I have to take when i get the bike stripped and can see where i want to go..

A clean slate..

That`s kind of how I’m looking at this now.. and to repeat my headline and to use one of all times greatest cliché : A clean slate..

So I have already fired up the machines and started to make som turnings, just have about one million ideas that i need to either bring with me or discard.

First item ready..

Let`s just take some time to celebrate the builds first item finished, Yay!! 🙂

The Gauge pod for the Gas tank design is ready for the final touches, the leather straps intended to hold it against the tank will be made at a later stage.

It`s the Motogadged MST that is going to be mated with this pod and I hope the match will be esthetically good

Picture above to illustrate the idea of the straps holding the pod firmly attached to the gas tank.

Some more pictures from process and finished piece.

An email has been sent!

This spring I was in contact with Mr John Williams at the Scotland based company TheTankShop, John generously spent a good 45 minutes with me on the phone explaining his methods and what I could expect, and please remember that this is in Scotland – about 2 flights for me and not exactly somewhere i can check both progress and design anytime I feel like it .

After thinking far and hard I`ve send them an email with my raw inspiration guidelines, hoping they will accept the job and also accept my ideas and incorporate them like i visualise them in my head 🙂

- There will be a Monocoque design, i.e i want the tank/seat and the rear end to flow as one.

- The finnish will be raw aluminium, possibly with visible welding – to honour the racing pedigree from the 1950´s

- I have decided to imbedded a Pod for the Speedo into the side of the tank(the Alu pod from the post above) , This will be held in place by suede leather straps.

The above design guidelines should place me in a territory I think I’m alone, not the mono design, that has been done to perfection by others before and is nothing new, however I’m very exited to see the results og my solution for my speedo.

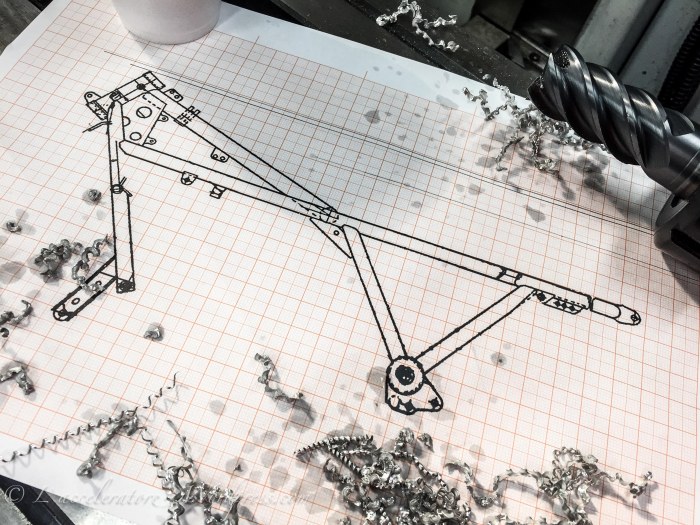

This is just coarse rendering of what i imagine and belive me, it took some careful thinking before i posted my drawings here… I`m going to take a class one day 🙂

And he answered!!

After having sent my ideas to Mr. Williams, I got a reply yesterday, and im am hoping that we will accept me as a client and help me reach the goals i have set.

And from the postman..

At some point i will try to make my own headlamp, but for now and for mockup and design phase a aftermarket hedlamp will do, i got this off the classifields and it should do the job for now, kid of like it too.. has the halo and everything.

Fiddling about in the workshop.

I am trying to find out how I want the layout and design of my handlebar controls, and i can tell you, it’s not easy.. clamp on? integrated ? buy or self-made.. just a part of the build i suppose, and to honest i kind of like the puzzle of getting it all together.

So I have done some mockups of switches and tried different ways of mounting them.

Below you can see one of my integrated options, the original hardware is from Motogadget and is the famous m.switch, I really like the feel of the switch and the thing is built like a tank, if compared to other brands.

But to quote Eamonn Walker – as the blood thirsty dictator Andre Baptiste Senior, in the 2005 movie Lord of War, also starring Nicolas Cage :

“Thank you, but I prefer it my way”

So I clamped it down in the lathe and sent it on a diet, the result can be seen below and to my needs it turned out fine.

The aluminium barrel was drilled and recessed, to determine how far and how long I can do in a CAD program, but there is a thing CAD software can’t to.. provide a live rendering of the feel of how it will feel in your hands.

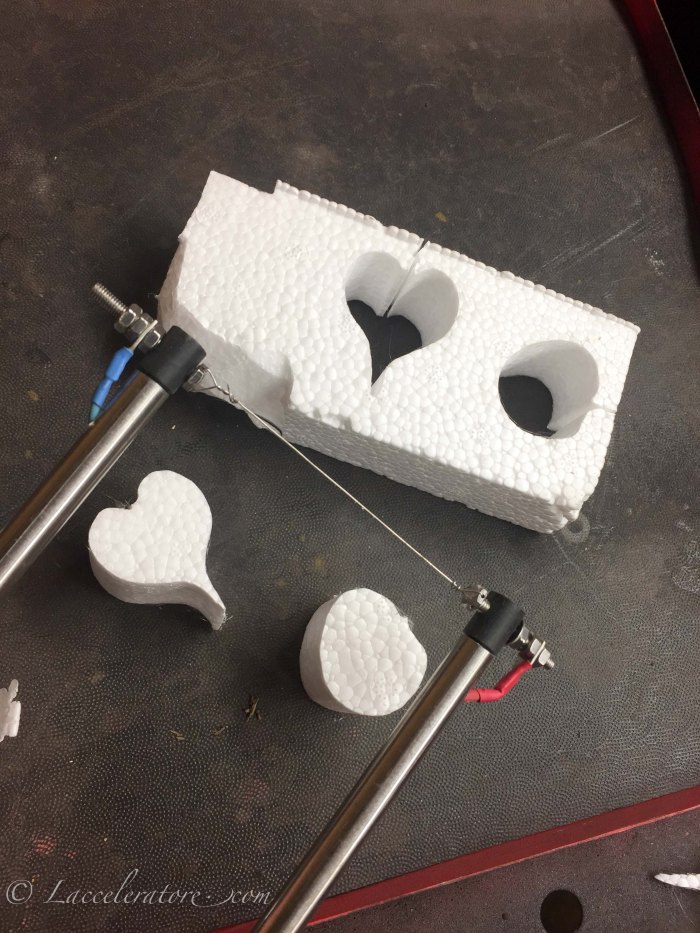

HWC – Hot Wire Cutter, my new favourite toy!

As my plans move forward and I need too start seeing how my drawings can look like in real life, to do so i have been experimenting with different types of material to make shapes from and i have landed on high density foam.

But I don’t want my shop to look like it`s been snowing inside and i don`t want the dust from grinding – to the rescue – The hot wire cutter !

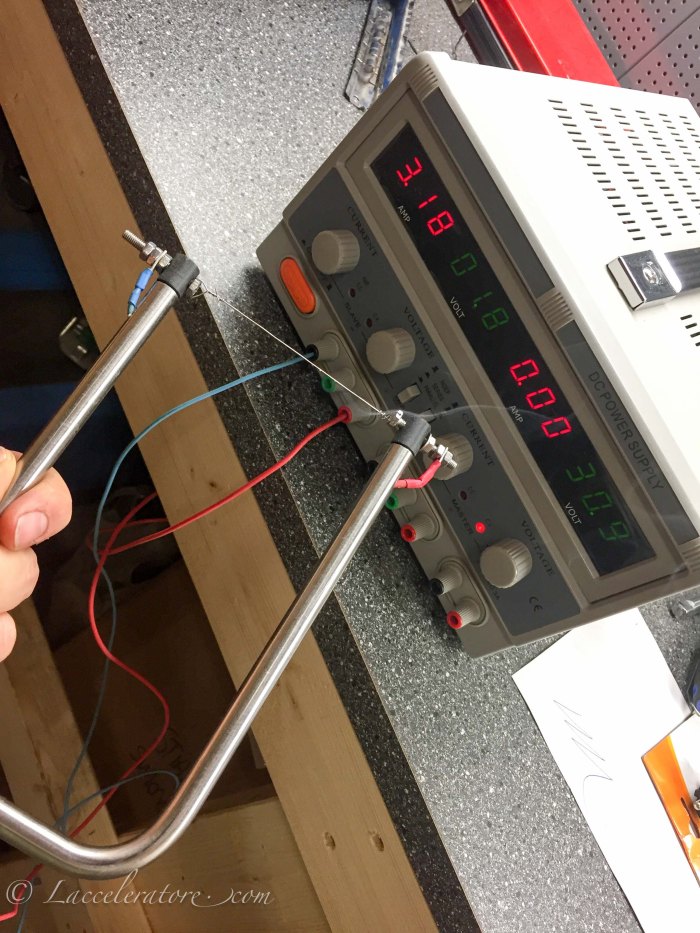

For another side project concerning electroplating I bought a big direct current (DC) generator from a workshop , it has 3 channels – where 2 of them are adjustable from 0-30 Volts and 0-5 Amps, they can also be run in parallel giving me a total of 0-60 volts and 0-10 Amps. and the best, it was dead cheap!

Ohm`s Law baby!

I took a piece of tubing, 10mm in diameter and bent it into a U shape, took a standard 0,8 mm Stainless steel string and attached it tho the ends.. and cranked up the amps until it started so sink into the styrofoam – and then I gave it some more juice just to get the cutting speed up a bit..

Works like a charm!

Next project is to make a Cutting table that can be used to make more precise items.

From Germany with love..

Since one of the key features of the bike was to keep it as “clean” and true to my design as possible there were actually no way arround getting a smart system to handle electricity.

Delivering the whole package at sensible prices Motogadget m.unit Blue was chosen accompanied by their m.Button and RFID lock system (This is also a feature when using the m.Unit Blue, but at the time it did not communicate with iOS so I got the key lock as an addition)

The alu pod posted here earlier has also been mated with a MST Tiny, looks great to me 🙂